Products

Seamless stainless steel tubes

Seamless stainless steel tubes

TUBACEX Group is mainly devoted to the manufacture and sale of seamless stainless steel and high-nickel alloy tubular solutions.

Our product portfolio covers dimensional ranges from 3 mm to 219 mm (8”) OD, and up to 42” in the case of mechanical trepanning.

TUBACEX stands as a top-tier tubing manufacturer, globally recognized for stainless steel and high nickel alloy tubes and pipes. In collaboration with our customers' R&D, our products are engineered to the exact needs of the most challenging customer specifications including Alloy 28, Super Duplex, Duplex and G3 with full control of the production process, from melting to final delivery to destination and support services at the rig site. With global approvals and acceptance, Tubing and Casing manufactured by TUBACEX is widely used in the CRA OCTG market.

CO2 Injection Tubing, Production Tubing, Production Casing, all with a variety of proprietary connections tested to the highest standards, are included in our comprehensive portfolio of CRA OCTG Tubing and Casing.

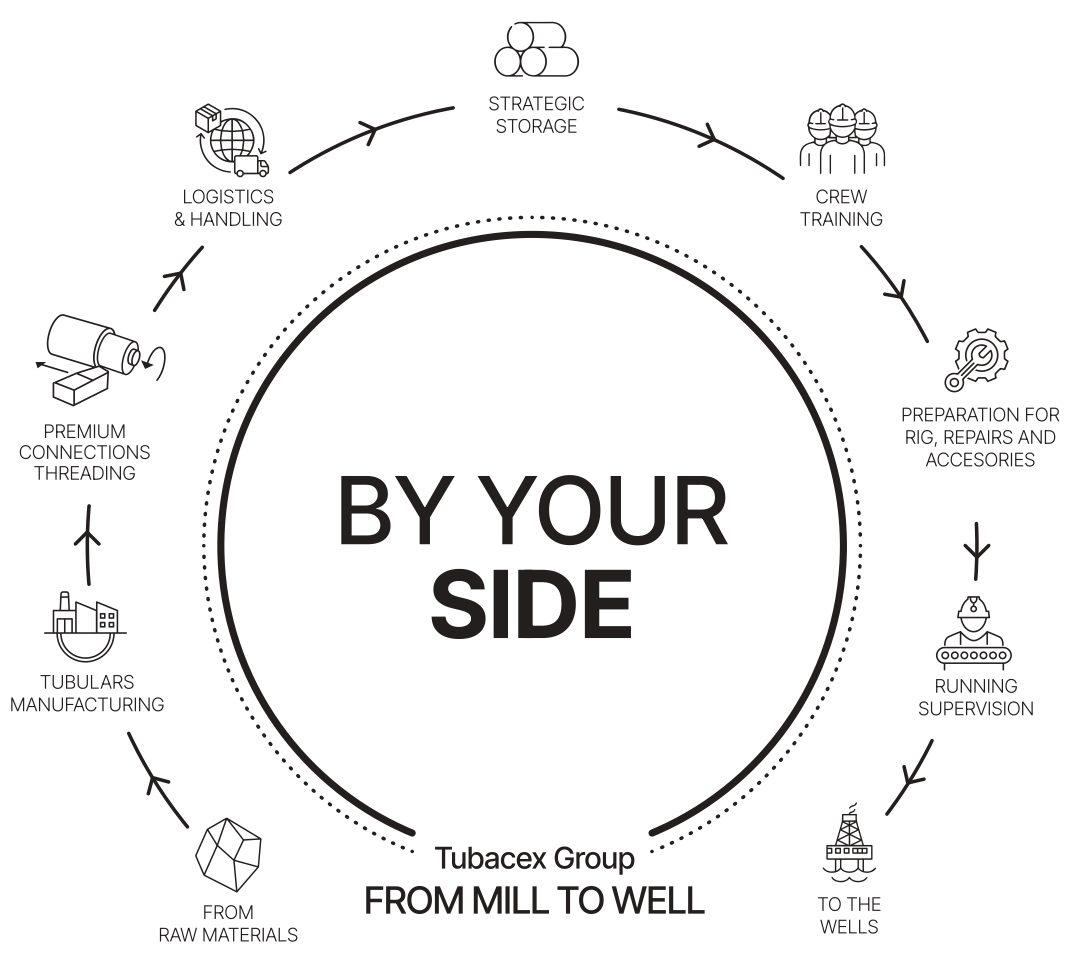

End-to-end solutions

Our approach to project management centers on minimizing the total cost of ownership by integrating supply and inventory management, guaranteeing availability regardless of location or time. Tubacex tailors its management for each project based on customer requisites, employing a comprehensive Tubacex toolbox that encompasses API Q2 and project management standards.

Tubacex has established itself as a global leader in designing, manufacturing, and installing advanced industrial products as well as supplying high-value added services for the OCTG industry.

BY YOUR SIDE

Comprehensive management services span various facets, encompassing tubular management, rig preparation, inspection, and rig return management. This holistic management package underscores Tubacex’s commitment to delivering value through seamless project execution.

Tubacex manages each project as per customer requisites. All the stages of the supply chain, from pipe manufacturing to running operations, are led by a global project management, governed by an API Q2 QMS. Our approach to project management focuses on minimizing the total cost of ownership by integrating supply and inventory management, guaranteeing availability at the rig site regardless of location or time, delivering value through seamless project execution.

The nexus of handling and running seamlessly converges with Tubacex’s Dynamic Traceability System. The final product bears a bidimensional matrix code and a corresponding tracking number. These codes are intelligible through laser readers and software and through smartphones, facilitating effortless control of products during handling and running operations.

Each operation is automatically logged within the system, ensuring real-time updates and access to comprehensive product information. Tubacex’s logistical operations assume a pivotal role in the global supply chain. Comprehensive services cover various areas, encompassing tubular transportation, storage and inventory management, as well as packing and on-time delivery.

Our extensive network of service centers, strategically positioned across the world, encompasses the day-to-day needs of the rig site, offering tubulars and connections inspection, rig preparation, rig returns management, accessories and repairs.

Check the catalogue for more information.

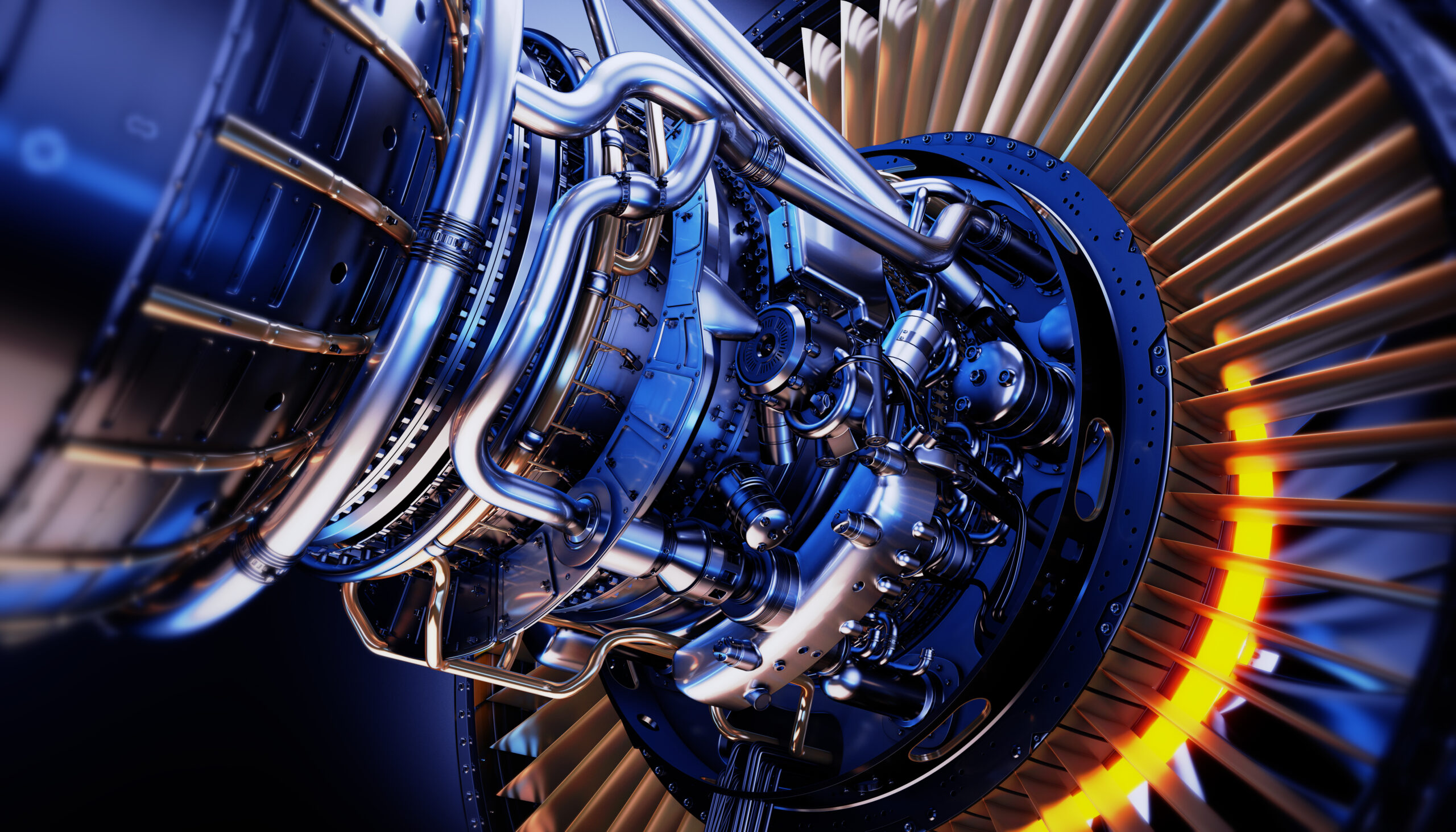

Aerospace and Defense applications demand high-performing precision tubing that meets strict dimensional and surface specifications. For decades now, Tubacex has consistently delivered quality annealed and tempered tubing to meet the exacting needs of the aerospace industry as well as U.S. military applications. Our tubing products are used for a variety of applications within the sector, including fuel, hydraulic, bleed, and cooling lines, as well as for landing and structural components.

Through its plants TUBACEX manufactures premium instrumentation tubing that can perform in the most demanding environments. Ideal for upstream applications, such as hydraulic pumps and flow monitoring devices, as well as topside processing facilities and subsea manifolds, Tubacex steel tubing maintains strict adherence to ASTM specifications to ensure that sizes and pressures have been considered to provide perfect compatibility with market-ready valves and fittings.

STRAIGHT-LENGTH

At Tubacex, we have the capability to manufacture straight-length H&I tubing in accordance with all ASTM, MIL-T and AMS specifications in an wide range of alloys/grades – more than 25 different grades in fact. Additionally, beyond being able to supply tubing with “standard” internal roughness (typically 40 Ra or higher), now TUBACEX can also supply the same tubes with Ra values as low as 10 µ” – without electropolishing-in wall-thickness up to 0.049” – making TUBACEX’s H&I tubes among the smoothest on the market.

COILED TUBING

Tubacex can produce seamless coiled tubing in outside diameters (OD) as small as 1/4” and up to 1-1/4” and in lengths exceeding 2,260 ft (depending on OD and weight). Moreover, TUBACEX’s coiled tubing is manufactured to the same restrictive tolerances as our straight-length H&I tubing. On long tubing runs, coiled tubing can significantly reduce installation time and eliminate labor costs associated with having to weld shorter 20 ft stick tubing. It is also ideal for underground applications where mechanical joints are not allowed or highly restricted.

Consult the catalogue for more information.

Tubacex heat exchanger tubing portfolio is manufactured in more than 25 different alloys – from austenitic to corrosion-resistant nickel alloys. And with three more specialized manufacturing plants strategically located in industrial hubs across the globe, Tubacex stands as the premier tubing manufacturer, maintaining the largest portfolio, size range, capacity, and reach in this product segment.

Tubacex can manufacture and supply heat exchanger tubing in sizes ranging from 12 mm to 88,9 mm OD. All standard outside diameter and wall thickness for heat exchanger tubing are covered with maximum lengths of 30 meters. Tubes can be supplied in straight or U Bends. Special sizes can be made on request.

Heat exchangers are important components in the oil & gas, refinery, chemical, petrochemical and power generation industries. The need of higher efficiency in heat transfer processes and the need of improved characteristics against corrosion have increased the demand on the quality of the seamless stainless steel tubes used in these applications. The Tubacex Group has a high competence on the development and manufacturing of such tubes.

Consult the catalogue for more information.

Subsea umbilicals are control lines used in offshore wells where Christmas trees (an assembly of control valves, gauges and chokes that control oil and gas flow in a completed well) are installed on the ocean floor. Umbilicals make up part of Tubacex SURF (Subsea Umbilicals, Risers jumpers, manifolds, loops and Flowlines) package of tubular products for offshore resistant to sea water environments and fluids transmitted through the tubes and with high corrosion resistance to sea water.

A key point in our strategy was to take the decision of making a huge investment in a state-of-the-art new mill, fully dedicated to the production of umbilical tubing. This new production unit integrates the best available technologies and know-how to produce the best quality product. Highly automatic facilities and a fully integrated traceability system contributes to a very costly efficient product.

For the past years almost any Subsea oil production system in the world utilized Super duplex steel within their umbilical tubes, due to high corrosion resistance in sea water, excellent mechanical properties and resistance and durability. Two superduplex grades are available.

Quality management Product Standards (some examples) Approvals (some examples)

- ASME / NCA-3800

- ISO 9001:2008

- ISO/DIS 13628-5

- ASTM A789

- ASTM A1016

- ANST SNT-TC-1A

- NAS 1638

- ASME BPVC Section V and Section IX

- ASME B31.3

- SAE AS 4059

- NORSOK M-650

- ISO 17025 for laboratories

- PED 97/23/EC

- Approved manufacturer status from TüV Lloyd’s register, DNV, Germanischer Lloyd, BV, etc.

- IBR well-known steel maker

- AD2000, werkblatt WO

In addition to standard straight-length tubing, TUBACEX offers a full range of medium and high pressure tubes in various alloys including 304, 316, 317, 904L, Duplex and Super Duplex, 6MO and Alloy 625.

Our medium and high-pressure stainless steel tubing can be supplied in 1/8-hard condition and manufactured in strict accordance with customer specifications to ensure a secure fit. The tensile strength of these tubes is generally 40 percent higher than annealed tubing of the same dimension and weight.

For more information visit our catalogues.

- Stainless steels: austenitics, including stabilized grades.

- Alloyed and martensitics steels.

- High Nickel alloys.

- Ferritic – austenitic: Duplex and Superduplex

- Hot-finished seamless stainless steel tubes.

- Cold-finished seamless stainless steel tubes.

- Welded and drawn pipes.

- Mechanical trepanning.

- Big OD Thin Wall Seamless Pipes.

- ASTM, ASME, DIN, EURONORM, ISO, BS, AFNOR, JIS, GOST

- More technical specifications are available upon request.

For further information visit our catalogues.

We are global

Tubacex steel mill obtains EN 9100 certification, reinforcing its aerospace vertical integration strategy

Feb 19, 2026

This certification strengthens Tubacex’s position in high-specification aerospace supply chains and supports long-cycle growth in advanced industrial applications. Acería de Álava (Aceralava), Tubacex’s specialized steel mill, has obtained EN 9100:2018 certification for aerospace manufacturing....

Tubacex secures three new umbilical tube orders worth €26 million

Feb 12, 2026

Tubacex has signed three umbilical tube contracts worth a combined €26 million, lifting its order book in this high-value offshore Oil & Gas segment to a record level. The awards, from three global clients, span projects in the Gulf of Mexico, Brazil, the Europe–Mediterranean axis,...